🔹 Fire Fighting Pump Sets – Reliable Pressure Systems for Fire Protection

A fire pump is a critical component of a fire protection system, designed to provide the pressure required to supply water to fire sprinkler systems and hydrant systems during an emergency. Powered by either an electric motor or a diesel engine, fire pumps ensure uninterrupted water flow at high pressure.

The pump intake is connected either to the public underground water supply or to a static water source such as a tank or reservoir. The pump then boosts water pressure to sprinkler risers, standpipes, and hose systems to effectively combat fires.

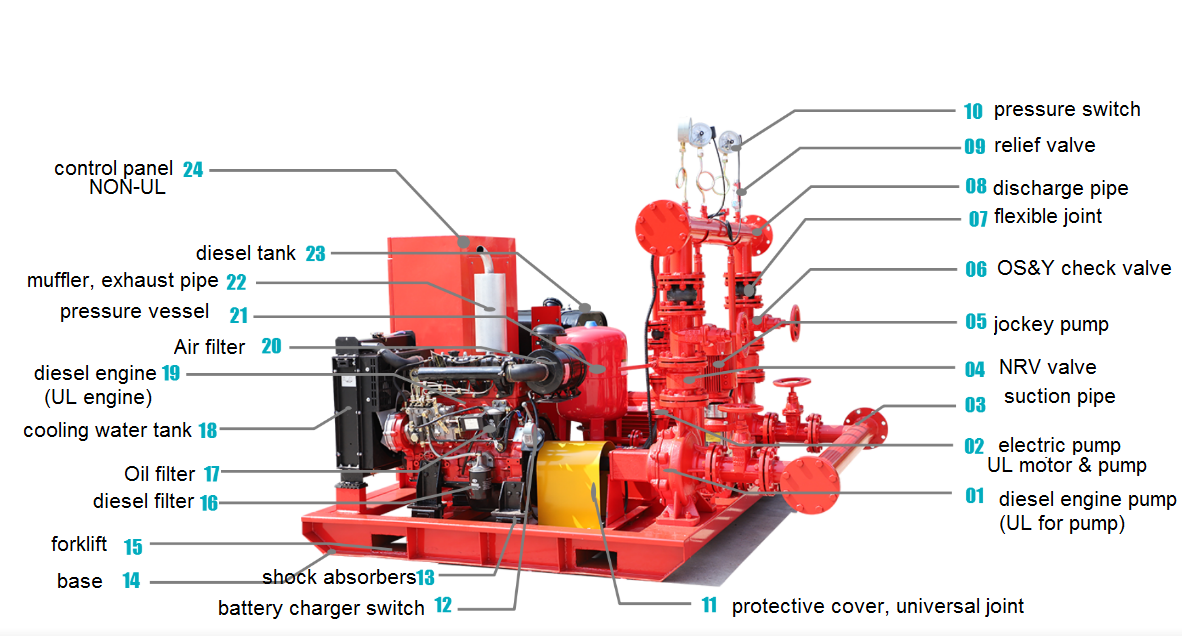

🔸 Fire Pump Package Components

All fire pump packages are engineered to comply with Local Civil Defense Authority Regulations and International Standards (NFPA 20 – National Fire Protection Association).

-

Electric Motor Driven Fire Pump

-

Options: Single stage, horizontal split case, end suction, multistage

-

Materials: Cast iron, stainless steel, bronze impellers

-

Reliable and efficient for continuous operation in commercial and industrial facilities.

-

-

Diesel Engine Driven Fire Pump

-

Backup to the electric motor pump with equal capacity and head.

-

Equipped with fuel tank, water tank fan, and control box.

-

Ensures firefighting capability even during power failures.

-

-

Electric Motor Driven Jockey Pump

-

Vertical multistage design.

-

Smaller capacity but higher head than main pumps.

-

Maintains system pressure during leaks or minor fluctuations.

-

Prevents unnecessary cycling of main fire pumps.

-

-

Control Panel

-

Automatic control for electric, diesel, and jockey pumps.

-

Includes overload and over-current protection.

-

Ensures smooth operation with reliable monitoring and safety mechanisms.

-

-

Accessories

-

Check valves, gate valves, pressure vessels (0.6MPa, 1.0MPa, 1.6MPa).

-

Pressure gauges, sensors, suction/discharge piping.

-

Flexible joints and flanges for easy installation and maintenance.

-

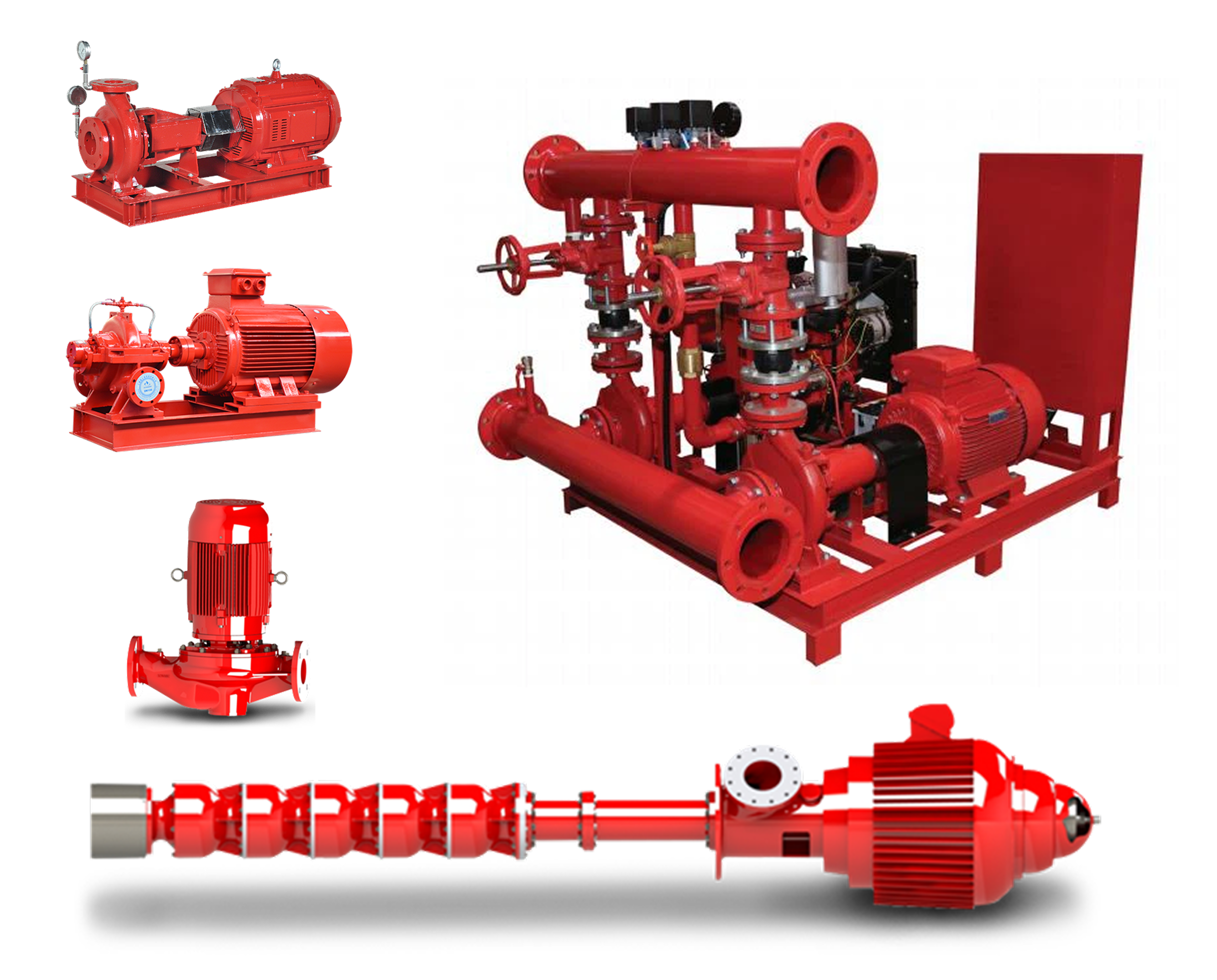

🔸 Types of Fire Fighting Pumps

-

End Suction Fire Pump

-

Compact with moderate floor space requirement.

-

Flexible mechanical room layout.

-

Available in both electric and diesel models.

-

Easy to service but limited to 1500 GPM maximum.

-

Single suction design reduces hydraulic efficiency.

-

-

Horizontal Split Case Fire Pump

-

Wide flow and head range.

-

Serviceable without disturbing piping and driver.

-

Requires large installation space.

-

Restrictions due to rotation direction.

-

More costly and complex to maintain.

-

Available in both electric and diesel driven.

-

-

Vertical Turbine Fire Pump

-

Ideal when flooded suction cannot be maintained.

-

Suitable for underground tanks or reservoirs.

-

Operates under suction lift.

-

Wide flow and head range, available in electric & diesel models.

-

Higher installation and service cost.

-

-

Vertical In-Line Fire Pump

-

Compact, reliable, and cost-effective.

-

Easy to service with minimal space requirement.

-

Available up to 1500 GPM maximum.

-

Electric drive only (not available in diesel).

-

✅ Why Choose Anti-Fire Expert Fire Pump Sets?

-

Fully compliant with NFPA 20 and Civil Defense regulations.

-

Wide range of pumps: End Suction, Horizontal Split Case, Vertical Turbine, Vertical In-line.

-

Available in electric, diesel, and hybrid configurations.

-

Complete packages with pumps, jockey, control panels, and accessories.

-

Built for maximum efficiency, reliability, and long service life.

-

Trusted by industries, commercial complexes, and critical infrastructure.